If there is one thing that bazaar has always celebrated about Kuwait, it is the entrepreneurialism, enterprise and sheer drive that we see from the residents here. This time we are particularly impressed by a local non-profit initiative Shield Kuwait founded by Fatemah Khalfan, that tackles the issue of how to prevent a virus 1/80 billionths of a meter in diameter from infecting us all, by lowering the ‘R number’, which is the number of people to whom an infected person will pass on the virus. We do that through washing our hands, social distancing, using disposable gloves and face masks, but an additional aid is the face shield, which looks a bit like a Flashdance welder’s protective helmet, or Lady Gaga’s visor depending on your preferred pop culture reference.

We managed to land an interview with the Head of Design and Production for Shield Kuwait, Hussain Albaghli. A graduate of Architecture from the University of Plymouth and Design Architect at Gulf Consult B.C. (before coronavirus), he felt immediately compelled to join Shield Kuwait, and tells us more about his role, the initiative and how you can help.

What is your personal involvement with Shield Kuwait, is there a team that works with you, and how did the initiative come about?

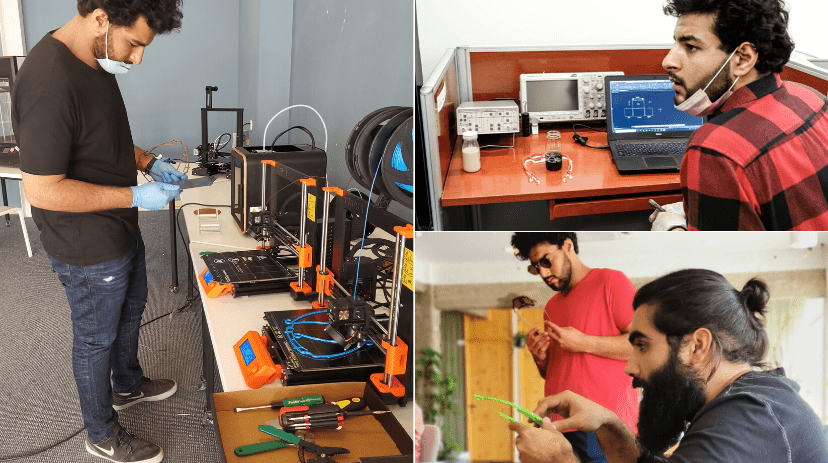

I got involved with Shield Kuwait from the very beginning, when I submitted my name on a volunteer list calling for individuals with 3D printing expertise for the purpose of producing Personal Protective Equipment (PPE) for Kuwait’s frontliners. Our first meeting was on the 9th of April, and since then, the Shield Kuwait Team operates in four locations: NIU Business District One, Kuwait College of Science and Technology, Kuwait Institute for Scientific Research and Kuwait Society of Engineers. I began by managing the NIU location, as Gulf Consult entrusted me with two of their 3D printers, and which I’ve been operating at a 24-hour capacity since mid-April.

The Shield Kuwait Team is fluid in nature, where volunteers come and go. Based on their technical skill and expertise and how much they are able to contribute in terms of time and effort, they are allocated a role. My role organically became Head of Design and Production, as the mission supporting frontliners is what drives my participation.

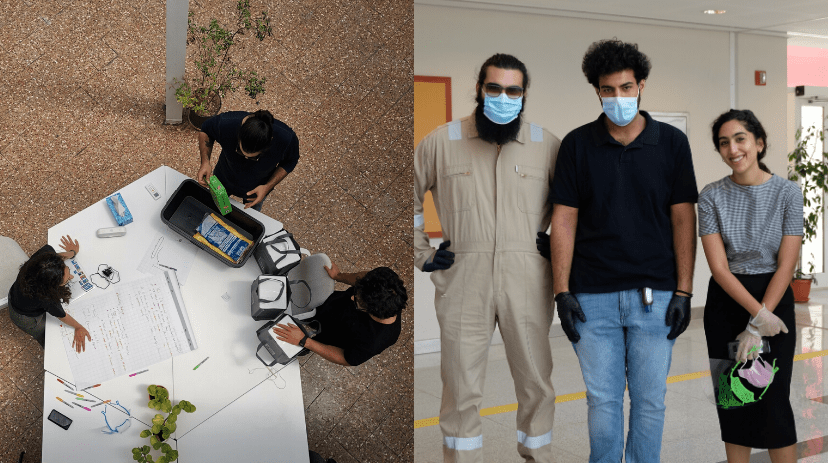

The team operates in an iterative and collaborative way, whereby Eng. Abdulhadi Bosakher – in charge of Shield Kuwait’s Research and Development, and Ms. Mariam Al Deehani – the lead on Medical Guidance, outlines a COVID-19 problem in the realm of PPE and collaboratively, Shield Kuwait then designs a solution. This process typically takes three to five days of finding a solution, after which, we seek out medical professionals to approve the design and provide feedback.

The team consists of four main people, Fatemah Khalfan our strategist and the person who started the initiative, Abdulhadi Bosakher our R&D analyst, Maram Al Deehani our medical expert.

On top of this, we have an amazing group called Q8 Volunteers who act as a support function in terms of daily distribution of face shields to Kuwait’s frontliners, social media, and overall daily operation.

Can you briefly describe 3D printing or “additive manufacturing”?

Additive manufacturing is the use of an apparatus to produce three dimensional (3D) objects. This manufacturing process enables us to produce complex shapes using minimal material based on the coding of the file required by the mainframe of the 3D printer.

While additive manufacturing enables you to produce complex shapes using less material, it stands to reason that you may not have had all the materials you needed to get the job done. How does Shield Kuwait source the materials needed?

Fortunately for us, we’ve had ongoing support from the public and private sector. In terms of the private sector, Kuwait College of Science and Technology (KCST), Gulf Consult and NIU stand as the main supporters. Gulf Consult has provided us with materials, equipment, packaging resources and it stands to reason that all of this has enabled us to increase production of face shields and therefore, also increase how many face shields we give to Kuwait’s frontliners on a daily basis. In terms of NIU, NIU welcomed the Shield Team from day one of operation, and provided a space for us to collaborate, design, produce, and distribute. NIU’s contribution is crucial in the sense that it allowed Shield to expand effectively without the constraint of space. In KCST, they offered us their fabulous laboratories and provided us with an assembly line of KCST students to quicken the production line. For this, we are proud to call them our key partners.

Additionally, we have received donations of 3D printers from AGi Architects, Australian College of Kuwait, Equate, and individual donations.

Do you require donations of raw materials and what’s the best way to donate and where to?

We are always in need of raw materials as more materials and equipment enable us to increase our production and therefore, more PPE for frontliners. For material donations, contact us on Instagram @shield.kuwait or email us on kwtshield@gmail.com and we will inform the donor of materials we need and where to deliver them to.

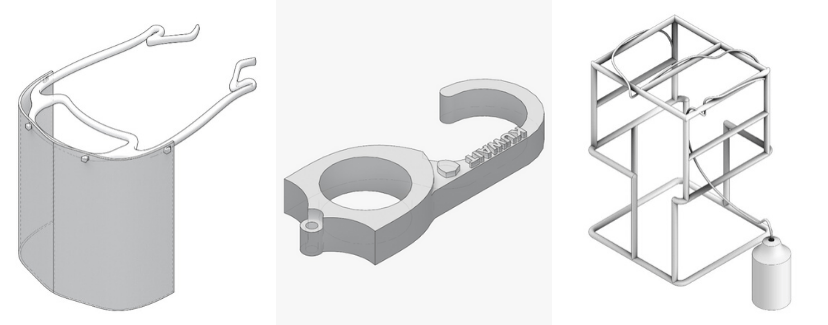

We are always accepting more resources, as our operation is dependent on donations and contributions to create more than just face shields. Shield Kuwait isn’t simply producing face shields, it has also successfully delivered intubation boxes, mask adapters, hands-free door openers, and is now in the phase of producing sanitization zones, and UV light boxes for hospitals to sterilize their PPE.

Ideas are many, but it’s putting these ideas successfully into action that is rare. Shield seems to have been established very quickly, how did this impressive response come about considering it takes design, resources, production, distribution and logistics?

We were gifted with a unique team with such a diverse skill set that the operation flowed organically.

How long did it take from the initial idea to getting the shields out, and where did they go first?

We managed to get the first set of face shields out on the second day, and gave them to doctors who are in the COVID-19 response team on the same day. That is, our production began with the first 3D printer we received, and since then, we have operated a twenty four hour capacity to meet COVID-19 needs.

Did the design for the shield come from your own engineers or was there an approved one in existence that Shield Kuwait replicated?

In the beginning we used an open source shield that is available online. After receiving feedback from medical staff who were using our face shields, Marc BouAssaf, one of our designers who is working from home, came up with a design to relieve the agitation caused by the open source design. We then proceeded to optimize the design in order to fit our fabrication process and are now successfully providing these face shields to frontliners too.

We have also successfully designed a non-3D printed face shield, as we discovered that the 3D printed face shield can’t handle Kuwait’s heat. This new shield is currently in the phase of mass production and is 100% Kuwaiti design between Eng. Abdulhadi BoShaker, Marc BouAssaf and I.

We see the shield used in conjunction with face masks. What is it about the design of the shield that makes it so vital to prevent the spread of COVID-19?

The face shield is vital because COVID-19 is a virus that spreads through aerosol droplets so things such as a cough, sneeze, spewing nasal, throat secretions and just talking spreads it. Therefore having a face shield is actually more effective than just a standalone surgical mask or the N-95 mask as the face shield fully protects your face. In a sense, the two things complement one another and provide full coverage.

How many shields have been made and distributed so far? Is there a process that vital businesses can go through to apply for the shields?

Over 10,000 face shields have been distributed thus far to frontliners who are people working in sectors that must remain open in order for the country to function such as medical staff, police, cooperative societies, police officers as well as Kuwait Red Crescent whose humanitarian role means they need face shields too to protect themselves.

Other institutions and bodies can apply through our link, however, we have a filtration system to evaluate need based on proximity of the frontliner to COVID-19 and allocate face shields based on this system. Ideally, we hope to provision face shields to all institutions and bodies in need.

Which types of facilities received the shields first?

COVID-19 medical teams are our top priority as their health and well-being is far too important at this point, and we managed to cover their needs in approximately a week of operation. As such, we began provisioning to medical hospitals, and have since shifted to facilities which have been converted into COVID-19 response, as well as clinics, police, and co-operative societies.

Co-operative societies are now also being delivered these shields to protect their staff. Where else are you hoping to deliver to and how do you decide the distribution priorities? Do you do this in conjunction with the Ministry of Health or do you have some autonomy?

Our filtration system means we deliver first and foremost to MOH and their medical staff. Furthermore, we have a benchmark of what constitutes first liners and as a team, we agreed that cooperative societies are definitely front liners as our national food supply is dependent on them. Their safety is also considered our safety as a nation and what we try to do is deliver whatever we have of face shield stock once it becomes available directly to the co-operative society.

Is there a way that bazaar readers can help Shield Kuwait with sourcing materials for production including sanitization, distribution, or in some other way that we may not be aware of?

Yes, please get in contact with us on Instagram @shield.kuwait and we will let you know if any of the materials you may supply can be put to use with us. Additionally, any type of support is welcome, not just donations. Since we consider ourselves a movement, the more people who want to help are welcome as the goal is to support our frontliners and this means more than donations.

Do you have any organizations or volunteer groups that you would like to thank here?

I would like to thank Gulf Consult, NIU and Kuwait College for Science and Technology for being our main sponsors and supporters throughout this initiative. As well as Sheikha Amthal AlSabah and Kuwait Volunteer Work Center for giving us an amazing group of volunteers.

Where do you see the future of additive manufacturing and has this crisis made the idea of 3D printing more viable for everyday usage, if it wasn’t before?

Additive manufacturing has shown us as a nation that it is possible to design and produce solutions for Kuwait’s future locally. Covid-19 may have outlined the urgency, but Shield Kuwait reflects the feasibility of this and we hope to carry on with this.

What is the one message that you would like to leave us with?

The last message would be to stay home and protect our frontliners. Their risk of contact with COVID-19 is high, and if as individuals we took on the responsibility of supporting them with our actions and behavior, we would be ensuring that the virus doesn’t spread too rapidly to them or to Kuwait as a whole.

STAY HOME TO PROTECT OUR FRONTLINERS.

If you would like to find out more on how you can help, please direct message @shield.kuwait or email them on kwtshield@gmail.com All images are courtesy of Shield Kuwait. Update July 2020: Shield Kuwait as a project is closed due to a return to work and numbers of PPE face shields being sufficient.